By Admin

By Admin Swing joints accommodate changes in water pressure within the irrigation system primarily through their flexible design and materials. Here’s a explanation of how they handle these changes:

Flexible Connections: Swing joints are designed with a sequence of 90-degree elbows that allow the entire assembly to flex and pivot. This flexibility is critical for absorbing and managing pressure fluctuations in the irrigation system. Unlike rigid connections, which can be susceptible to cracking or breaking under varying pressure conditions, the flexibility of swing joints helps maintain system integrity by reducing the risk of leaks and structural damage. The pivoting action ensures that the joint can move with the pressure changes, providing a buffer that protects the system’s components from excessive stress.

Durable Materials: Swing joints are typically made from durable materials such as polyvinyl chloride (PVC) or polyethylene. These materials are chosen for their ability to withstand a wide range of pressure conditions without compromising their structural integrity. PVC and polyethylene are known for their high tensile strength, resistance to cracking, and longevity, making them ideal for components exposed to frequent and potentially severe pressure changes. The use of these robust materials ensures that the swing joints can handle both high-pressure surges and low-pressure drops, maintaining the system's functionality and preventing premature failure.

Pressure Relief Mechanism: The design of swing joints includes a natural pressure relief mechanism. When water pressure increases, the joint's ability to flex and move helps to dissipate some of the pressure, thereby reducing the stress on the sprinkler heads and the piping system. This pressure relief function is essential for preventing blowouts, leaks, and other forms of damage that can occur due to excessive pressure. By allowing slight movement, the swing joint ensures that pressure is evenly distributed across system components, minimizing the risk of localized failures and enhancing overall system reliability.

Shock Absorption: Swing joints play a crucial role in absorbing shocks and vibrations within the irrigation system. These shocks can result from sudden pressure spikes, such as those caused by rapid valve closures or abrupt changes in water flow. The flexible nature of swing joints acts as a cushion, dissipating the energy from these impacts and preventing them from causing damage to sprinkler heads or piping. This shock absorption capability is vital for maintaining the long-term reliability and durability of the irrigation system, protecting it from the potentially damaging effects of pressure-induced stress.

Maintaining Alignment: One of the significant advantages of swing joints is their ability to maintain the correct alignment of sprinkler heads, despite changes in water pressure. Proper alignment is crucial for achieving uniform water distribution and irrigation efficiency. Swing joints ensure that sprinkler heads remain in their intended positions, even as the system experiences pressure fluctuations. This consistent alignment helps to avoid dry spots and overwatering, promoting healthy plant growth and efficient water use. By maintaining alignment, swing joints contribute to the overall effectiveness of the irrigation system.

Ease of Adjustment: In the event that pressure changes cause misalignment or other issues, swing joints offer the advantage of easy adjustability. Unlike rigid connections, which may require extensive disassembly or replacement to correct misalignments, swing joints can be quickly and easily adjusted to bring sprinkler heads back into proper alignment. This adjustability simplifies maintenance and allows for rapid responses to pressure-related issues, minimizing downtime and ensuring the continued efficient operation of the irrigation system. By providing an easy means of adjustment, swing joints help maintain the system’s performance and reliability over time.

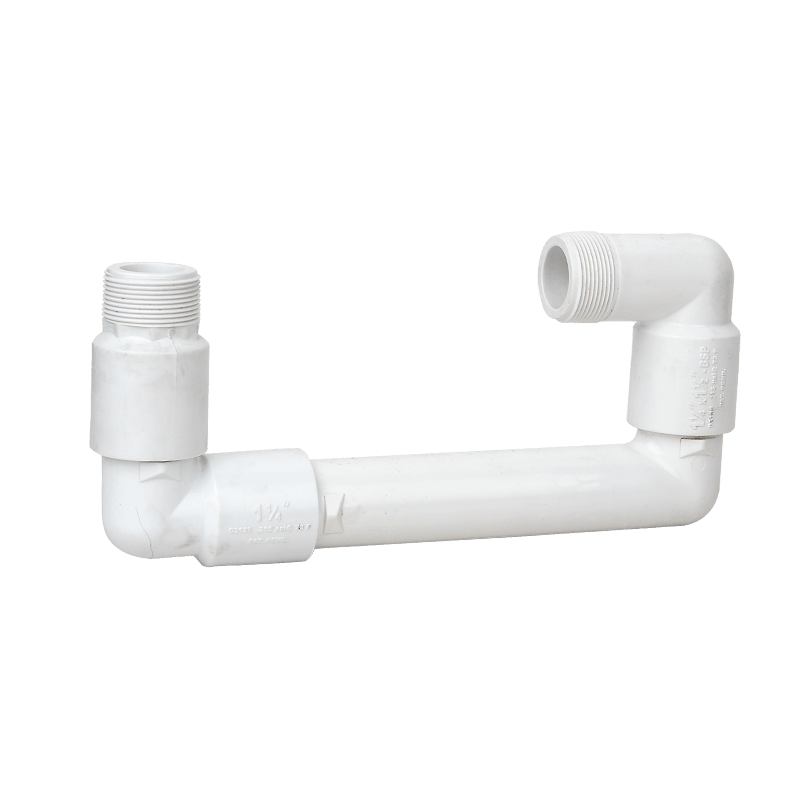

YR9201 BSP1-1/2"x1-1/2" irrigation swing pipe elbow