By Admin

By Admin Adjustable Positioning: Irrigation swing joints are pivotal in facilitating precise alignment and positioning of irrigation components. Their design incorporates a rotational mechanism that allows for angular adjustments, accommodating the unique requirements of various irrigation setups. This adjustability is essential when dealing with complex landscapes or uneven terrain, where the ability to fine-tune the angle and orientation of sprinklers or drip emitters ensures optimal water coverage. By allowing for such adjustments, swing joints ensure that each irrigation component can be positioned to achieve maximum efficiency, thereby enhancing the effectiveness of water application and minimizing waste.

Accommodates Ground Shifts: One of the most critical advantages of irrigation swing joints is their capacity to accommodate ground movements and shifts. In agricultural or landscaping environments where soil settlement, erosion, or ground subsidence are common, rigid irrigation connections can suffer from stress-induced damage. Swing joints, with their flexible design, absorb these movements, preventing the transfer of stress to the irrigation pipes and fittings. This inherent flexibility mitigates the risk of structural failures, such as leaks or cracks, which can arise from ground shifts. By maintaining system integrity despite environmental changes, swing joints contribute to a more resilient and reliable irrigation infrastructure.

Reduces Stress on Pipes: The operational longevity of an irrigation system is significantly influenced by the stresses placed on its components. Swing joints play a crucial role in distributing and minimizing these stresses by allowing controlled movement between connected parts. Unlike rigid joints that transmit stress directly to the pipes, swing joints absorb and diffuse mechanical forces, thereby reducing the likelihood of pipe fractures, joint separations, or leakages. This stress reduction not only enhances the durability of the irrigation system but also decreases maintenance requirements and prolongs the lifespan of critical components.

Eases Installation: The installation process for irrigation systems can be complex, particularly when dealing with varying site conditions. Swing joints simplify this process by offering a degree of flexibility that accommodates slight misalignments between irrigation components and the water source. This flexibility is particularly beneficial in scenarios where exact alignment is challenging to achieve due to uneven terrain or existing infrastructure. By reducing the need for precise alignment, swing joints streamline the installation process, making it more adaptable to diverse site conditions and reducing the time and labor required for successful setup.

Enhances System Maintenance: Routine maintenance and system adjustments are integral to the efficient operation of an irrigation system. Swing joints facilitate these activities by allowing for easy repositioning and realignment of irrigation components. This flexibility is particularly advantageous during maintenance procedures, as it reduces the need for extensive disassembly or reconfiguration of the system. Swing joints enable quick adjustments and modifications, thereby minimizing downtime and ensuring that the irrigation system remains operational with minimal disruption. This ease of maintenance supports ongoing system performance and efficiency.

Improves Water Distribution: Effective water distribution is a key factor in the success of any irrigation system. Swing joints contribute to this by enabling precise adjustments in the positioning of irrigation components. By allowing for fine-tuning of the angle and orientation of sprinklers or drip emitters, swing joints help achieve a more uniform distribution of water across the irrigated area. This optimization of water application reduces the likelihood of overwatering or underwatering specific zones, leading to improved plant health and resource efficiency. Enhanced water distribution also supports better crop yields and overall system effectiveness.

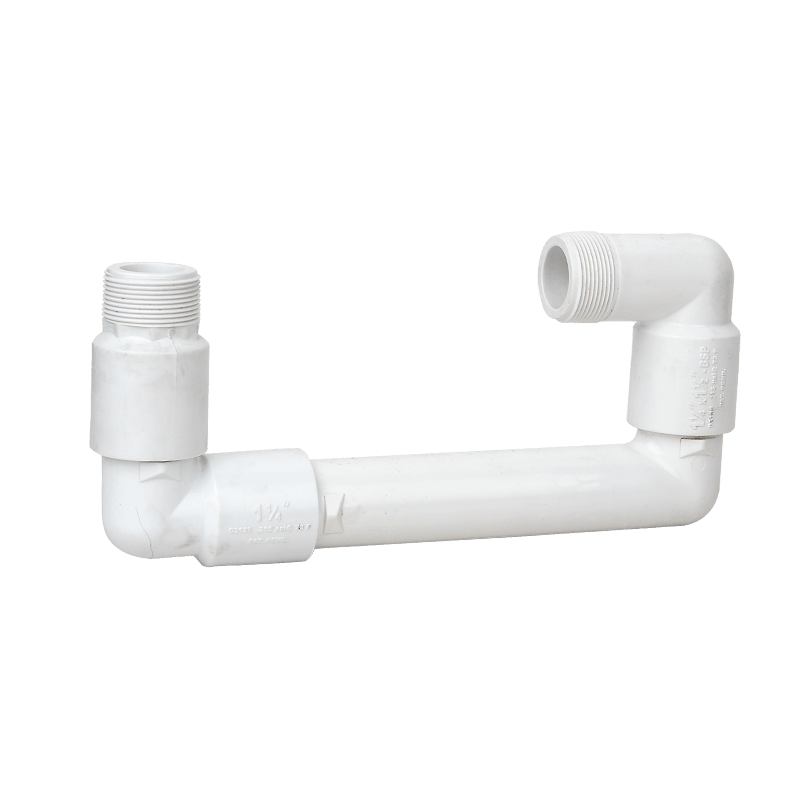

YR9201 BSP1-1/2"x1-1/2" irrigation swing pipe elbow