By Admin

By Admin The garden irrigation filter typically handles sediment and debris through its filtration mechanism. Here's how it generally works:

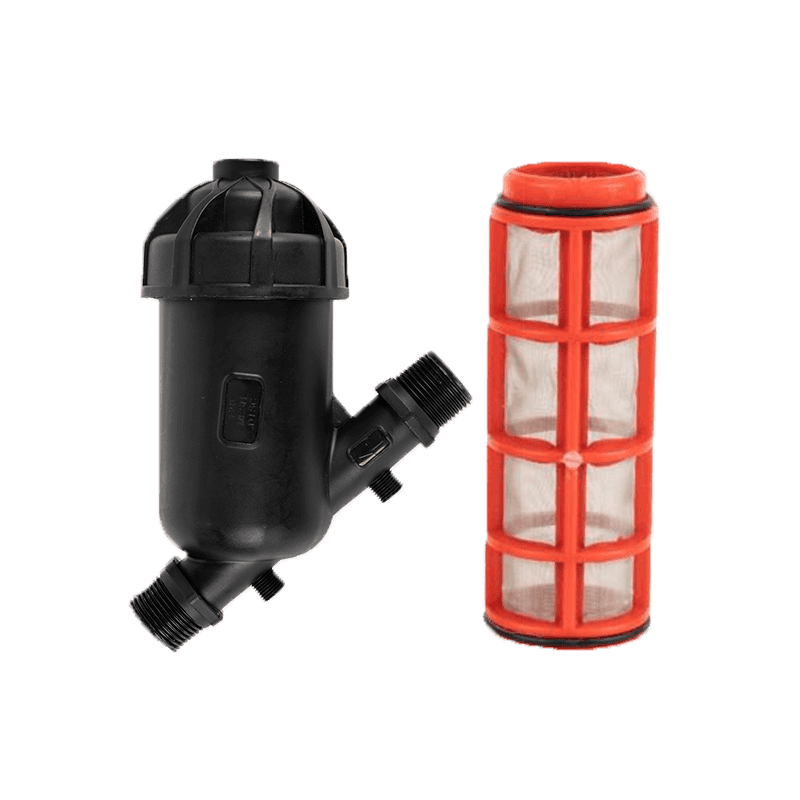

Filtration System Design: The design of a garden irrigation filter's filtration system is a masterpiece of engineering ingenuity. Engineers meticulously consider various factors such as hydraulic principles, material science, and fluid dynamics to craft a system that effectively separates contaminants from water without impeding flow. Every element, from the housing to the filter media, undergoes extensive optimization to ensure maximum filtration efficiency while maintaining structural integrity under varying operating conditions.

Mesh Size Selection: Mesh size selection is a crucial aspect of filter design, as it directly influences the filter's ability to capture particles of different sizes. Engineers conduct thorough analysis of the size distribution of contaminants commonly found in garden water sources to determine the optimal mesh size range. This involves sophisticated computational modeling and experimental validation to strike the perfect balance between filtration efficacy and hydraulic performance. The chosen mesh size is finely tuned to capture the target contaminants while minimizing pressure drop and maximizing flow rates.

Sediment Settlement Mechanism: In addition to the primary filtration media, garden irrigation filters often incorporate ingenious sediment settlement mechanisms to enhance performance. These mechanisms leverage principles of fluid dynamics and particle physics to promote the settling of larger particles within the filter housing. Through careful design and optimization, engineers create environments where sedimentation occurs efficiently, preventing particles from re-entering the water flow and causing clogs or damage downstream.

Flush Valve or Backwashing Feature: The inclusion of a flush valve or backwashing feature represents a paradigm shift in filter maintenance and longevity. These features empower users to actively manage filter cleanliness and performance, extending the lifespan of the filter cartridge and ensuring consistent water quality. Engineers meticulously engineer these systems to withstand high-pressure flushing while maintaining tight seals and leak-free operation. Advanced control algorithms and sensor technologies may also be employed to automate the backwashing process, optimizing performance and minimizing user intervention.

Pre-Filtration Stage: To provide an extra layer of protection against coarse debris, some garden irrigation filters feature dedicated pre-filtration stages. These stages utilize coarse media or specialized baffles to capture large particles before they reach the main filter element. Engineers carefully design these pre-filtration systems to minimize pressure drop and maximize contaminant removal efficiency. By intercepting bulky debris early in the filtration process, pre-filtration stages help prolong the lifespan of the primary filter media and reduce maintenance frequency, enhancing overall system reliability.

Regular Maintenance Protocol: A comprehensive maintenance protocol is essential to ensure the long-term performance and reliability of garden irrigation filters. Engineers work closely with usability experts to develop user-friendly maintenance procedures that minimize downtime and maximize efficiency. Detailed maintenance schedules, instructional videos, and interactive guides are often provided to guide users through the process step by step. Engineers may incorporate innovative features such as self-diagnostic systems and predictive maintenance algorithms to alert users to potential issues before they escalate, further enhancing user experience and satisfaction.

The YR9407B boasts a larger BSP1" length for increased water drift and greater filtration talents. Its Y-formed layout optimizes filtration efficiency, making it a really perfect desire for larger irrigation systems. This Y display filter is versatile and appropriate for a number of irrigation.