By Admin

By Admin Material Quality: The durability of micro sprinklers hinges significantly on the materials used in their construction. High-quality materials such as UV-resistant plastics (like polyethylene or polypropylene) or corrosion-resistant metals (such as stainless steel or brass) are preferred. These materials are chosen for their ability to withstand prolonged exposure to sunlight, fluctuating temperatures, and chemicals commonly found in irrigation water and soil. UV-resistant plastics prevent degradation and brittleness over time, while corrosion-resistant metals ensure longevity in corrosive environments. Such robust materials minimize the risk of cracking or breakage, which can occur under extreme cold conditions.

Freeze Protection Features: In regions prone to freezing temperatures, micro sprinklers equipped with freeze protection features are crucial. These features typically include components like freeze-resistant seals, valves, or drains designed to prevent water from freezing inside the sprinkler system. For instance, freeze-resistant seals are engineered to expand slightly if water inside them freezes, preventing cracking or damage to the seal itself. Automatic drain valves are another common feature that ensures water is expelled from the system before freezing occurs. Some advanced micro sprinkler systems also incorporate insulated components or materials that maintain operational integrity in sub-zero temperatures without compromising water distribution efficiency.

Installation Depth: Proper installation depth is essential to protect micro sprinklers from freezing. The depth at which micro sprinklers are installed varies based on soil type, local climate conditions, and the specific design of the sprinkler system. Generally, micro sprinklers should be buried at a depth where they are insulated from surface frost. This depth minimizes exposure to freezing temperatures and reduces the risk of water inside the system freezing and expanding, which can lead to cracks or ruptures in pipes and fittings. Adequate installation depth is critical for ensuring the longevity and reliable performance of micro sprinklers throughout the year, especially during winter months.

Drainage System: Effective drainage systems are fundamental to the durability of micro sprinklers in freezing conditions. Proper drainage prevents water from accumulating and freezing inside the sprinkler lines, which can cause significant damage. Gravity-based drainage systems or the use of automatic drain valves are common methods to ensure water is expelled from the system after each irrigation cycle or during periods of inactivity. Automatic drain valves operate based on pressure changes within the system, opening to release water when the system is turned off. This proactive approach to drainage helps maintain dry conditions within the sprinkler system, minimizing the risk of freeze-related damage to pipes, fittings, and emitters.

Climate Adaptation: Choosing micro sprinklers specifically designed for cold climates enhances their durability and performance in freezing temperatures. Manufacturers offer products tailored to withstand the rigors of cold weather, incorporating features and materials that mitigate the effects of frost and ice. These specialized micro sprinklers may include reinforced components, enhanced insulation, or strategic design elements that improve resistance to freezing and ensure consistent water distribution. Additionally, implementing winterization practices such as insulating exposed pipes, covering sprinkler heads with protective caps or blankets, and using temporary heating solutions can further safeguard micro sprinklers during prolonged periods of freezing weather.

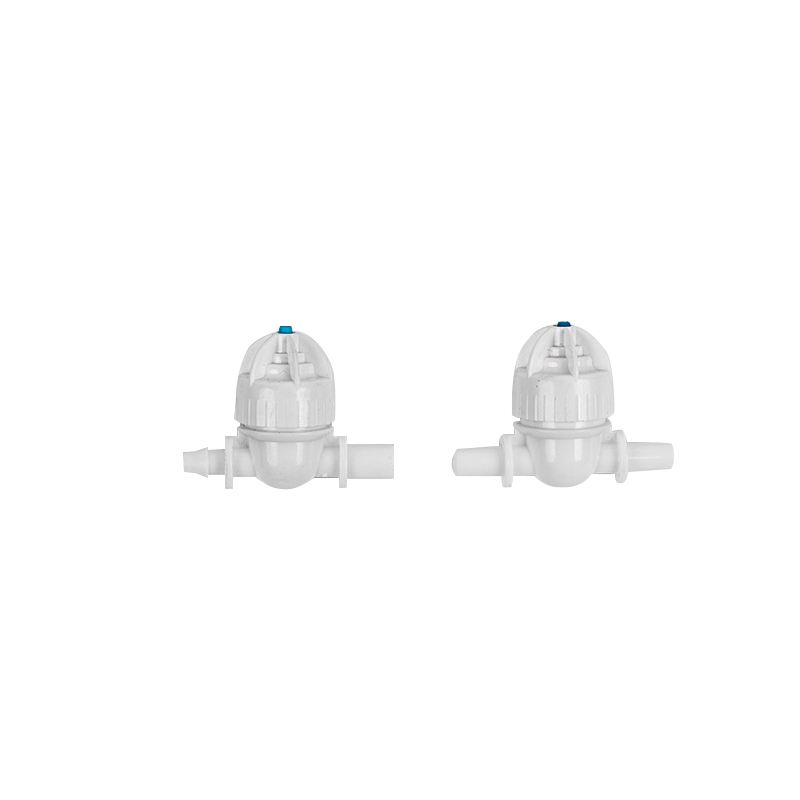

YR9820 anti-drip device atomizing nozzle connector