By Admin

By Admin Reduced Water Pressure: When a filter becomes clogged, the water flow through the irrigation system is obstructed, causing a noticeable decrease in pressure. This drop in pressure can be measured using a pressure gauge at different points in the system. Reduced pressure not only affects the system's ability to distribute water evenly but can also impair the performance of irrigation components such as sprinklers and drip emitters. Monitoring pressure levels regularly and comparing them to the system’s specifications can help in identifying filter issues before they become critical.

Uneven Water Distribution: The clogged filter impedes water flow, leading to uneven distribution across the irrigation zones. This can result in some areas receiving insufficient water while others might receive too much. To assess this, compare the output in different zones using flow meters or by visually inspecting the coverage patterns. Uneven watering can cause uneven plant growth, increase susceptibility to pests and diseases, and lead to inefficient water use, which could necessitate a filter inspection and possibly an adjustment or replacement.

Increased Energy Consumption: The pump or motor in an irrigation system may work harder to push water through a clogged filter, resulting in increased energy consumption. This can be quantified by comparing the system’s energy usage data over time. Energy meters or system logs can provide insights into changes in power consumption. Higher energy costs not only affect operational budgets but also indicate that the system may be under stress due to filter blockage. Addressing filter issues can help restore energy efficiency and reduce costs.

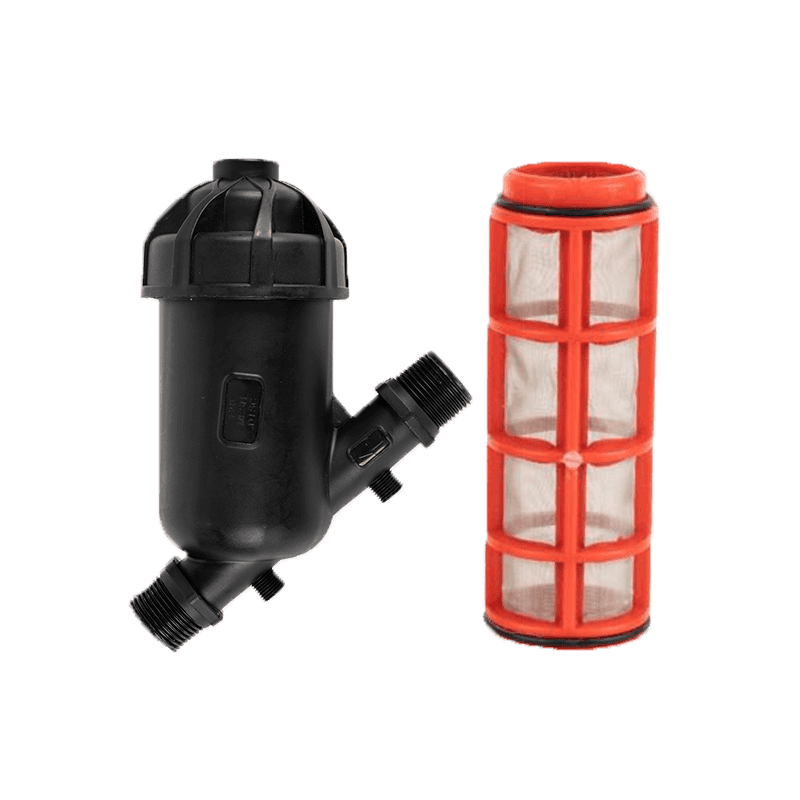

Visible Debris Accumulation: During routine maintenance, if you observe a buildup of debris such as dirt, sand, or organic matter on or around the filter, this is a strong indication of clogging. Thorough inspection of the filter element (whether it is a screen, disc, or sand filter) can reveal the extent of blockage. For screen and disc filters, you might need to remove and clean the filter elements regularly to maintain optimal performance. Sand filters might require backwashing or media replacement.

Unusual Noises: Air or turbulence caused by water flowing through a partially blocked filter can produce unusual sounds such as hissing, whistling, or gurgling. These noises can be detected through careful listening and are often indicative of air being drawn into the system or water flowing erratically. To address these issues, check for blockages in the filter and ensure that all system components are properly sealed and functioning. Unusual noises are often a precursor to more significant issues and should be addressed promptly to prevent further damage.

Longer Irrigation Cycles: If you notice that the irrigation cycles are taking longer than usual, it could be due to a clogged filter causing reduced water flow. Extended irrigation cycles can lead to overwatering in some areas, which can harm plants and lead to water wastage. By monitoring the duration of irrigation cycles and comparing them with the system’s normal operating times, you can identify anomalies. Adjustments to the filter or system settings may be needed to restore efficient watering schedules.

Increased Backwashing Frequency: For filters that require backwashing, a noticeable increase in the frequency of backwashing can signal that the filter is becoming clogged. Backwashing is a process where water is flushed through the filter in the opposite direction to remove trapped debris. Frequent backwashing not only indicates a higher level of debris but can also strain the system and increase maintenance costs. Establishing a routine for backwashing and assessing filter performance can help determine if the filter needs cleaning or replacement.